Color coating

Category

Color Coated Board

Deails

Color coating production line:

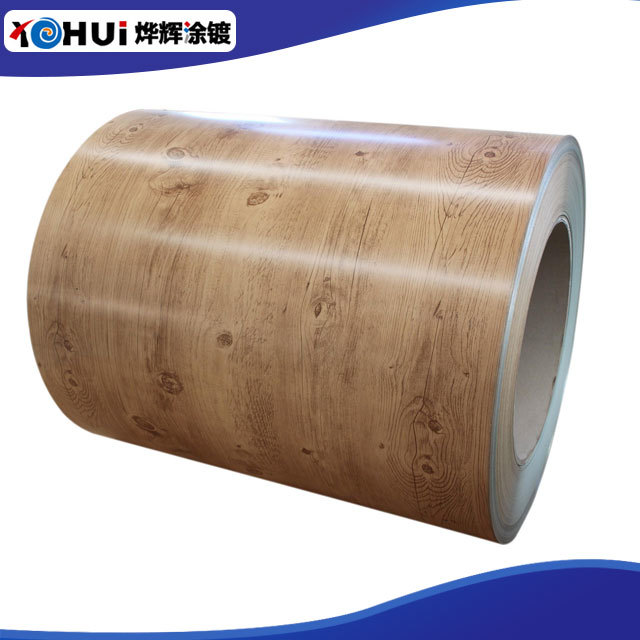

The color-coated steel plate is a new type of building material that has been rapidly emerging in the world for nearly 30 years. It is refined on the continuous unit by

chemical pretreatment, initial coating and coating. The quality of the coating is much more uniform, more stable and more desirable than the one-piece spraying or

brushing of the molded metal surface.

Since the color coated steel sheet has excellent decorative property, moldability, corrosion resistance, and strong coating adhesion, the color can be kept novel for a

long time. Therefore, the color coated steel plate can obtain good economic effects such as steel substitution, efficient construction, energy conservation, and

pollution prevention, and it is an ideal material for today's manufacturing of slabs.

Color coated steel plate:

Generally, it refers to a product obtained by surface-treating a substrate, coating (rolling) a coating or bonding an organic film, and baking it into a final product.

Foreign countries call it "pre-coated steel plate" and "plastic steel plate". The product has a beautiful color or pattern when it leaves the factory, so it is also called

"color coated steel plate". In China, the color coated steel plate is more popular, and is referred to as “color coated board” or “color board”.

The company's main color plate specifications: thickness 0.12-1.5MM, width 500-1250MM; unit fastest speed: 150M / MIN; coating layer types include: polyester,

silicon modified polyester, polyurethane, polyvinylidene fluoride, high poly Ester, epoxy resin, acrylic acid, etc. The production line has the ability to meet the

production of mid-range products such as building boards and home appliances. The line adopts two-coating and two-baking production process, and the process is

complete. The drying furnace adopts an electric heating straight hot air circulation system.

Color coated steel coil application areas:

Box type container

Various vending machines, display cases, cans,

compressive containers, collection rooms, etc.

Furniture and office equipment

Home appliances, furniture, automotive industry, security doors, blinds, etc.

Transportation industry

Automobile and train interior decoration,

partitions, containers, barriers, ship

compartments, air purifiers, various types of

panels for ships, oil purifiers, front panel of

driver's seat, etc.

Agricultural equipment

Desiccant and other agricultural equipment,

greenhouses, silos, shells, warehouses, etc.

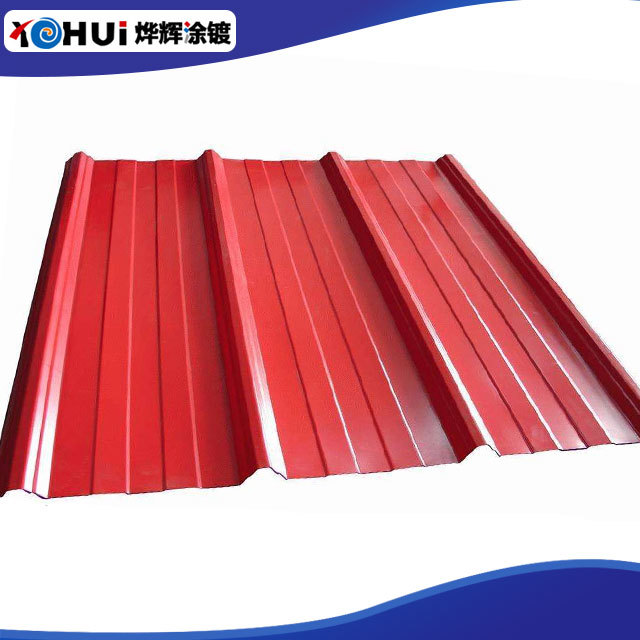

Architectural and structural engineering

Large-scale project site interior, outdoor wall,

roof, corrugated use. Construction sandwich

panels insulation, drainage systems, ventilation

systems and other architectural uses.

Underground works, parking sheds, telephones,

guest rooms, waiting rooms, and home

decorating purposes.

Electrical and lighting equipment

Refrigerators, washing machines, switch cabinets,

instrument cabinets, air conditioners, microwave

ovens, bread makers, freezer compartments,

fluorescent shades, switchboard boxes, motor

boxes, photocopiers, etc.

-

- Color coating

LEAVE MESSAGE

MORE PRODUCTS

More Products

undefined